PTX EXPLAINED

Converting power into other forms of energy

"Power-to-X" refers to a set of technologies that convert electrical power into other forms of energy, such as hydrogen (Power-to-Hydrogen), synthetic fuels (Power-to-Fuels), or other valuable chemicals. It enables the storage and utilisation of renewable energy in various sectors, contributing to a more sustainable energy system.

Advanced power supply and controls

We develop and manufacture power conversion and control systems that optimise the integration of renewable energy into PtX.

Our offerings encompass specialised power units and end-to-end electrolysis power supply systems for the production of green hydrogen and other PtX applications.

Sophisticated control systems and software enable efficient energy management and coordination of PtX processes. These control technologies contribute to maximising energy efficiency and ensuring reliable operation of PtX solutions.

By integrating our expertise in power electronics and controls, we support the development and scaling of electrolyser systems and PtX solutions which are crucial for the transition to sustainable energy.

Experts in grid compliance

Leveraging our expertise in wind energy, we play a key role in ensuring grid compliance within the PtX industry.

By incorporating advanced grid-compliant solutions from the wind energy into PtX power supply technologies, we can ensure that the energy generated aligns seamlessly with grid requirements.

This involves integrating grid-friendly features within wind turbines and associated technologies, such as smart inverters and control systems. These measures enhance the ability of PtX systems to adhere to grid regulations, maintain stability, and contribute effectively to the overall energy grid.

Being experts on grid compliance, we address the critical aspects of reliable and compliant renewable energy integration into the broader energy infrastructure.

A strong track record

25+

years of power conversion

design experience

15 GW

annual production capacity

exceeding 15 GW

3500+

units of converters

and rectifiers per year

Delivering PtX converters, rectifiers and power supply systems to top electrolyser OEMs.

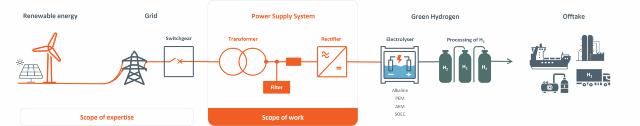

SCOPE OF WORK - GREEN HYDROGEN

Power Supply System for electrolysers

Reliable and efficient power supply systems for electrolysers.

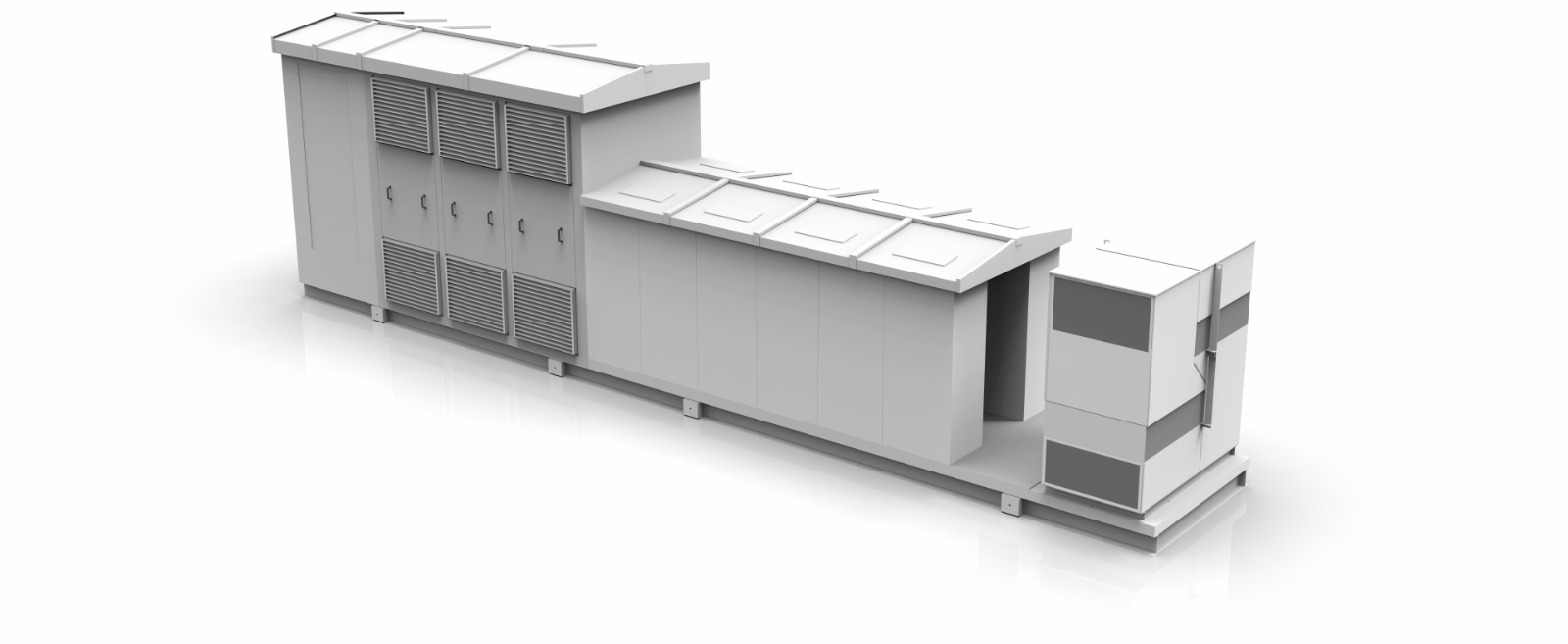

INTEGRATED SYSTEMS

End-to-end power supply system

Our modular power supply systems are available as containerised or skid solutions and includes; transformer, rectifier, cooling and controls. We offer a customised solution built on proven technology.

1

1Switchgear

The switchgear is typically supplied by the local power utility to control and protect electrical equipment, ensuring safe and efficient operation.

Adapted to customer requirements:

- Switchgear location depends on electrolyser plant layout. In small-scale setups, we offer to include the switchgear in our power supply system.

Transformer

The transformer adjusts the voltage levels to meet the specific requirements of the electrolysis process. It also provides electrical isolation between the high-voltage grid and the electrolyser, enhancing safety and system reliability.

Adapted to customer requirements:

- MV level (grid)

- AC LV level adapted to electrolyser and rectifier technology

- Power output matching electrolyser

- Winding layout designed to cancel harmonics

Power Supply

Our high efficiency electrolyser DC power supply (rectifier) supports voltage levels and functional control requirements for all known electrolyser technologies.

Including options for:

- Passive or active front-end rectification

- Active power factor control

- QVAR production

- Compliance to low or high grid requirements

- Fault Ride Through

Cooling

The cooler efficiently dissipates heat generated during the electrolysis process, ensuring optimal operating temperatures. It helps maintain the efficiency and longevity of the system by preventing overheating.

Adapted to customer requirements:

- Re-cooling unit (shown)

- Heat exchanger connected to central plant cooling

The switchgear is typically supplied by the local power utility to control and protect electrical equipment, ensuring safe and efficient operation.

Adapted to customer requirements:

- Switchgear location depends on electrolyser plant layout. In small-scale setups, we offer to include the switchgear in our power supply system.

The transformer adjusts the voltage levels to meet the specific requirements of the electrolysis process. It also provides electrical isolation between the high-voltage grid and the electrolyser, enhancing safety and system reliability.

Adapted to customer requirements:

- MV level (grid)

- AC LV level adapted to electrolyser and rectifier technology

- Power output matching electrolyser

- Winding layout designed to cancel harmonics

Our high efficiency electrolyser DC power supply (rectifier) supports voltage levels and functional control requirements for all known electrolyser technologies.

Including options for:

- Passive or active front-end rectification

- Active power factor control

- QVAR production

- Compliance to low or high grid requirements

- Fault Ride Through

The cooler efficiently dissipates heat generated during the electrolysis process, ensuring optimal operating temperatures. It helps maintain the efficiency and longevity of the system by preventing overheating.

Adapted to customer requirements:

- Re-cooling unit (shown)

- Heat exchanger connected to central plant cooling

* Example of 6 MW electrolyser power supply system (scalable up to 12 MW)

Electrolyser Power Supply

Scalable power supply

Designed to reduce cost, complexity and ensure a low failure rate.

Constructed from preconfigured and modular building blocks, the power supply for electrolysers accelerates time-to-market.

The modular platform introduces cutting-edge IGBT technology and enhances power density, allowing for parallel operation of up to 4 subsystems and scalable up to 12 MW Electrolyser systems, supporting from megawatts to gigawatts hydrogen plants.

Our engineering competencies enable the customisation of solutions for specific customer needs, adhering to proven standards while meeting site and grid requirements, making us the chosen provider by leading electrolyser OEMs.

Pre-configured building blocks

Modular building blocks to enable fast time-to-market.

In the rapidly evolving landscape of PtX applications, the integration of preconfigured building blocks stands as a cornerstone for achieving cost-competetiveness and fast time-to-market.

These building blocks are not just accelerators for project deployment, but they also play a pivotal role in facilitating scalability for customers.

This scalability is directly applicable in the diverse and demanding contexts of PtX applications, where adapting to changing needs is crucial.

Robust and efficient global supply chain

The cost-effectiveness of green hydrogen is heavily reliant on a robust and efficient global supply chain.

At KK Wind Solutions, we lower cost and complexity through global manufacturing. Being the biggest converter manufacturer in the wind industry, we utilise our knowledge, global footprint and scale to bring down costs.

Our resilient supply chain meets the dynamic demands of the PtX market, combining advanced technology with a global reach to develop and deliver end-to-end power solutions for electrolysers.

Learn more about our end-to-end power supply systems for electrolyzers and PtX applications.

Complete the contact form to connect with one of our specialists.