How to Select the Right Rectifier for Your Green Hydrogen Plant

Discover three key rectifier technologies for a green hydrogen plant's power supply unit and how to choose the one that best meets your power quality needs and grid requirements.

As green hydrogen production becomes increasingly vital in the renewable energy landscape, it is essential to ensure that all systems in the plant’s power supply unit are efficient, reliable, and cost-effective. The rectifier unit plays a vital role here, as it drives the electrolysis process by converting alternating current (AC) into direct current (DC).

For project developers and electrolyzer OEMs, selecting the right rectifier is a complex balancing act, made even more challenging by the trend of increasing megawatt sizes in hydrogen plants. This demands careful consideration of power quality, cost-effectiveness, and grid compliance, ultimately balancing capital and operational expenses.

This article examines three rectifier technologies often discussed with clients, guiding you to choose the best option for your green hydrogen plant by balancing power quality, cost-effectiveness, and grid compatibility.

Thyristor technology

Since its introduction in the 1960s, thyristor technology has been recognised for its stability and low intrinsic losses, making it a traditional choice for high-power DC voltage applications.

Though thyristor rectifiers offer capital cost advantages, they generally produce low power quality due to a poor power factor and high harmonic content. This requires capacitor banks and system-level filters to enhance power factor and eliminate harmonics, which otherwise cause grid losses.

In some cases, 24-pulse systems are necessary, complicating and enlarging phase-shift transformer designs. These additional measures lead to increased costs and efficiency losses in hydrogen plants, factors often initially overlooked.

“A thyristor rectifier cannot independently supply reactive power or actively provide ancillary grid services and fault ride-through. This limitation requires additional systems, like capacitor banks, at the hydrogen plant level to manage reactive power needs and ensure grid compliance, underscoring its less grid-friendly nature,” explains Michael Ariel Nielsen, Head of Power-to-X at KK Wind Solutions.

In summary, thyristor technology is well-proven and has high intrinsic efficiency. However, to meet ancillary grid service, power factor, and harmonic requirements at the plant’s point of connection, additional filters, phase shift compensation, and control systems are necessary. This increases the plant’s cost, complexity, and losses beyond the rectifier.

Diode technology

The diode rectifier is the simplest type, converting AC to DC without active controls. However, a DC/DC module, or chopper, is needed to adjust the DC voltage output for hydrogen production. The maximum DC voltage output is limited by the LV AC input, reducing maximum system power density and restricting diode rectifiers to specific electrolyzer types.

Diode rectifiers are known for high internal efficiency but often produce a power factor below 1, necessitating power factor compensation filters and MV transformers that can handle higher currents at the plant level.

“Diode rectifiers require additional filters to handle harmonic currents and voltages. Like thyristor rectifiers, a 24-pulse system can reduce harmonics but requires phase-shift transformers, adding complexity and costs. Larger green hydrogen plants using diode rectifiers might also need complex control systems to manage power factor at the point of connection,” states Michael Ariel Nielsen.

In summary, although diode rectifiers offer high efficiency, efficiency losses occur elsewhere in the system due to low power factor and required filters. Additionally, they can complicate interactions with other plant components.

From a grid compliance perspective, diode rectifiers are reasonable when power quality demands are low. However, as plant size increases, integrating diode rectifiers becomes more complex, shifting costs from the rectifier to transformers, filters, and control systems.

Active Front End (AFE) technology

The AFE IGBT (Insulated Gate Bipolar Transistor) rectifier is favoured for its precise, fast power and load control, ability to supply reactive power and support for ancillary grid services. These features and its quick disconnection capability have made it the industry standard in renewable markets like wind.

IGBT technology has progressed significantly since its inception. Initially known for higher failure rates than thyristor and diode technologies, it now has extensive applications in high-power electrical installations, making a return to traditional rectifiers unlikely.

“AFE IGBT rectifiers deliver high efficiency, rivalling diode rectifiers while maintaining a unity power factor and generating low harmonics. This optimisation reduces MV transformer requirements and system losses, often eliminating the need for additional megawatt filters,” says Michael Ariel Nielsen.

In summary, AFE IGBT rectifiers are versatile, supporting various electrolyzer technologies with voltages up to 1500Vdc, though a DC/DC module may sometimes be needed for lower DC voltages. Their adaptability ensures they meet diverse requirements.

From a grid compliance standpoint, AFE IGBT rectifiers excel in providing active, real-time grid support and ensuring swift responses to ancillary service demands from transmission system operators. They offer tailored solutions for specific needs, including supporting island-mode grids requiring rapid response for stability.

Factoring power quality and grid compliance into financial planning

Traditional options like thyristor or diode rectifiers may initially seem cost-effective when selecting rectifier technology. However, over a 20-30-year lifespan, these choices can lead to operational inefficiencies and increased maintenance costs for green hydrogen plants. They require power factor corrections, extra filters, and control systems to manage low power quality and meet grid compliance.

During a project’s initial phase, project developers and electrolyzer OEMs should consider power quality and grid compliance in financial calculations, as Michael Ariel Nielsen ends:

“Considering power quality and grid compliance ensures informed decisions that balance capital and operating expenses, optimising the plant’s economic performance. AFE (IGBT) rectifiers offer advantages by simplifying system design and generating capacitive power, potentially offering overlooked additional income.”

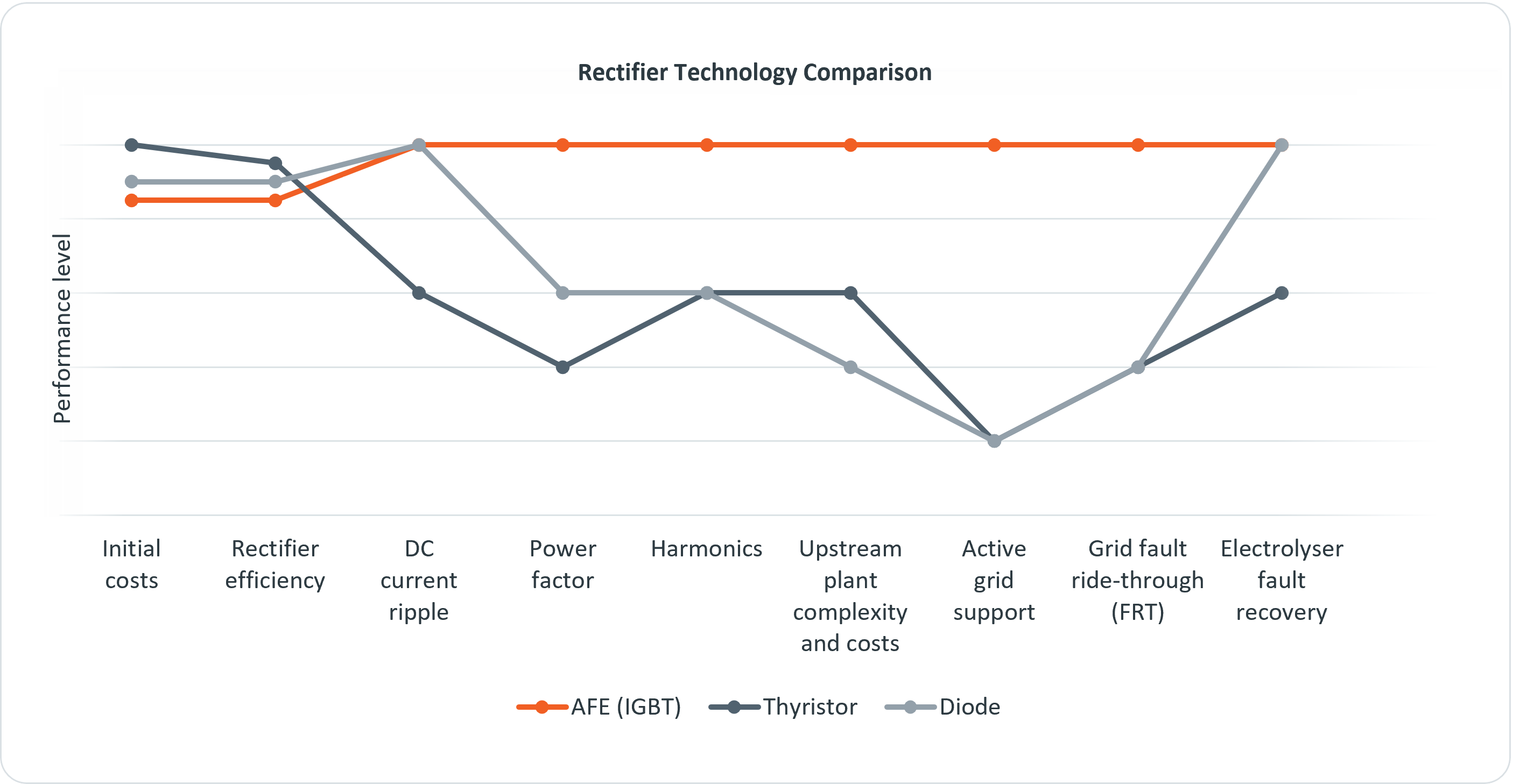

Below, we have compiled a performance comparison of the three rectifier technologies based on eight parameters identified in collaboration with our customers as key factors to consider.

About KK Wind Solutions

With over 40 years of experience, KK Wind Solutions is a leading systems supplier in the renewable energy industry. We apply our industry-leading grid compliance expertise from the wind industry to green hydrogen, ensuring seamless alignment with grid requirements.

A strong partner in Power-to-X

Learn more about our rectifiers

Explore our rectifiers that support various electrolyzer technologies and meet your specific requirements.